How to Dyno Tune a car?

By Carl Heideman

By Carl Heideman

Modern technology is changing how we interact with classic cars, and sometimes we can’t help but laugh. After all, these situations can get pretty anachronistic.

More and more, we rely on high-tech tools to keep our classics in tune. Static timing has been replaced by dynamic timing; reading spark plugs has been replaced by tailpipe sniffers; and the holy grail of tuning tools—the dynamometer— is generally within reach of any enthusiast.

While classic car owners and shops have quickly adopted most digital tools, the dynamometer still seems steeped in controversy and confusion. “Will it blow up my engine?” is a common question.

We’ve made thousands of dyno pulls, solving scores of problems and eking out lots of power along the way. We still haven’t blown up a single engine on the dyno. In fact, these sessions have saved many engines from an untimely demise by allowing us to catch and identify problems in a controlled environment.

1: No Fear

It’s human nature to fear what we don’t understand, and the dyno is no exception. Like most fears, however, this one can be erased by knowledge.

First off, there are two basic types of automotive dynamometer, the engine dyno and the chassis dyno. Think of it this way: the engine dyno tests engines that are removed from the car—the flywheel is bolted to the dyno—while the chassis dyno allows the engine to remain inside the car. With the chassis dyno, the car is strapped down so that the entire driveline spins the machine’s rollers.

There are also different dyno designs. Some use a water brake and a torque arm to measure torque. Others use an electric current (eddy current) to measure torque. Still others use math to calculate the acceleration of a known mass and derive horsepower and torque from there.

There are also different dyno designs. Some use a water brake and a torque arm to measure torque. Others use an electric current (eddy current) to measure torque. Still others use math to calculate the acceleration of a known mass and derive horsepower and torque from there.

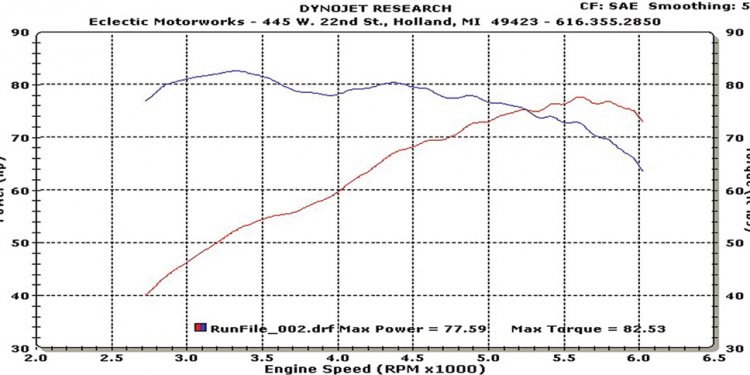

Once the torque at every single rpm point is recorded, the dyno’s computer can compute a corresponding horsepower figure. This info is displayed on a computer screen, and printouts are just a keystroke away.

While each design has its pluses and minuses, the chassis dyno has become much more common among the general population for the simple reason that the engine doesn’t have to be removed for testing. In fact, we have a bold statement about the subject: A chassis dyno session is one of the easiest and least expensive ways to put the finishing touches on a tune-up, solve a tricky drivability problem, or both.

2: A Chicken in Every Pot and a Chassis Dyno on Every Corner

While dial-back timing lights and wideband oxygen meters have been making their way into many people’s toolboxes, few of us have the space or cash to install a chassis dyno.

Maybe it’s a stretch to say that there’s a chassis dyno shop on every corner, but most people have one within an hour or two of home. Better yet, medium to large metropolitan areas tend to have multiple dyno shops.

How do you find one? Ask around. The local racers know whose shops are so equipped. Most of the dyno manufacturers also list their customers online. As far as cost, expect to pay about a hundred dollars for a baseline session.

Dyno shops secure the car to the ground with the same tie-down straps used on trailers. Know where your car’s mounting points are located, and don’t forget that the exhaust will get hot and the drive wheels will be moving very fast. You don’t want a strap melting or getting wrapped up on an axle during a run.

3: Don’t Get Started With the Last Step

Once people overcome their fear of the dyno, they seem to experience another phenomenon: they want to jump on the dyno too soon. As much as we value our dyno sessions, we usually save them for last in the tuning and diagnostic process.

Okay, there’s one time when we break that rule. Sometimes we baseline a new project just to get a starting point, but we consider that a luxury and not a necessity.

ecreative webmail human creation between reality and illusion creation of israel creativity lesson plans creation kit skyrim se creative zone creation from chaos examples creativity symbol relationship between creativity and innovation creativity beyond the myth of genius pdf creative memories beneath the pines album creation x570 creative form drawing creation l catalog creativity to go creativity xb kipling creativity pro color pink creativity to go creative engineering creation during pregnancy creative form drawing workbook 1 creative without cheats creativity out of the box thinking innovation creative fabrica creativity warm up mock object creation inside method creation of man painting opposite of creation myth creativity meaning creativity science reddit creation with felix pappalardi creation coloring pages creativity news creativity of language date de creation among us creation like word creation joy of creation ecreativeworks glassdoor creative & innovative thinking creation coffee creativity skills examples creation l customer service creativity vs originality